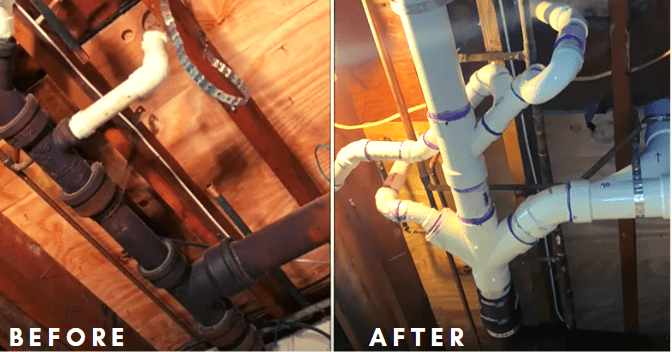

If your house was built prior to 1987, you likely have cast iron plumbing pipes in your bathroom or basement.

If your cast iron pipes are leaking or if you need to add a plumbing fixture for a bathroom renovation, you will likely find yourself in a situation where you need to cut your existing cast iron sewer pipe and replace it with PVC pipe.

Cast iron pipe can be effectively cut with a reciprocating saw, angle grinder, hacksaw, or snap cutter. Mark the cut line on the cast iron pipe using chalk and cut through the pipe by applying even pressure. Replace the cut segments of cast iron pipe with PVC pipe using Fernco flexible couplings.

Each method for cutting cast iron pipe and various tips and tricks for a successful project are outlined in the following sections.

Step 1: Prepare to cut your cast iron pipe

Before cutting cast iron pipe, you want to make sure that your existing pipe is properly supported. There are many different types of pipe supports that you can use to secure your cast iron pipe before cutting it. A few options are listed below:

- Hanger Strap (most common)

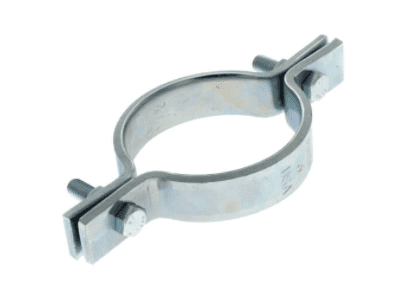

- Clamp Style Supports

- Riser clamp (for vertical sections of pipe)

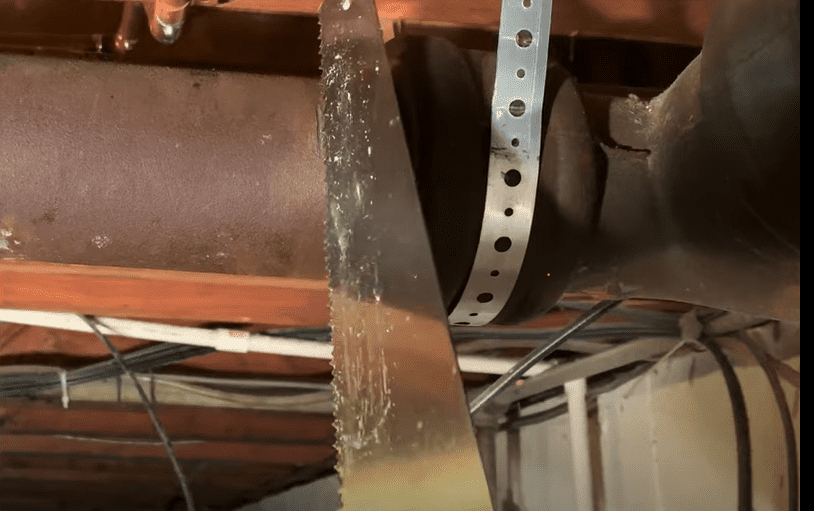

Use hanger strap (or similar) to support the areas of cast iron pipe before and after the segment you plan to cut. If you are cutting a horizontal section of cast iron pipe, it is recommended that a pipe support be installed at least every 5 feet of pipe run.

Typically, you will want to use a something called a “riser clamp” when you are cutting vertical runs of cast iron pipe.

Riser clamps are a two-piece support that screw together around your pipe. These create a “flange” around your cast iron pipe that bears onto the floor structure and supports your pipe.

There are plenty of different ways to support cast iron pipe. Just make sure that you give pipe support some thought before you begin cutting your cast iron pipe. Cast iron pipe is HEAVY and 3” diameter cast iron pipe can way as much as 10 pounds per linear foot. If unsupported, the pipe can fall or slip down through the floor (depending on your application) – resulting in damage.

Andrew Thron – ATimprovements, llc

Step 2: Mark the location of your cut on the cast iron pipe

Although you can use anything to mark the “cut” line on your cast iron pipe, pencil and pen typically don’t show up too well on cast iron. It is recommend that you use a crayon or chalk to mark your cut line. If you are using a snap cutter, there is really no need to mark the full circumference of the cast iron pipe.

However, marking the whole way around the pipe is helpful if using an angle grinder or a reciprocating saw. To do this, use a piece of yarn or wrap a sheet(s) of paper around the pipe and then trace along the edge of the yarn or paper.

Step 3: Cut the Cast Iron Sewer Pipe

Before you cut cast iron pipe, make sure that you are using the proper safety equipment such as:

- Safety glasses (face shield offers more protection)

- Ear plugs

- Gloves

Because cast iron pipe is typically used as gravity sewer pipe, it is recommended that you put some plastic down underneath of where you plan to make your pipe cut. Even if you avoid using your sinks and toilets for an hour before cutting your cast iron pipe, you will likely still experience some drips when you cut the pipe. Protect your floor and use plastic.

The following Sections detail the four most common ways to cut cast iron pipe.

Cutting Cast Iron Pipe with a Reciprocating Saw (Sawzall)

Cutting through cast iron pipe with a reciprocating saw can be accomplished in just a few minutes if done properly. In order to cut cast iron with a reciprocating saw, you will need to use a carbide tipped blade suitable for cutting through metal.

Once you have installed the carbide tipped metal cutting blade on your reciprocating saw, proceed with cutting through the cast iron pipe by following these steps:

- Mark the cut line on the cast iron pipe using chalk

- Use a hacksaw to establish a “groove” or “guide” for your reciprocating saw blade. This will help to keep your blade from moving outside of the cut line (optional).

- Apply even pressure and cut through the pipe using the reciprocating saw. This will likely take 1-2 minutes, depending on the condition of your pipe and blade.

The video below will show you how how I cut cast iron pipe with a reciprocating saw, step by step:

Cutting Cast Iron Using a Grinder

Cutting Cast Iron Pipe with an angle grinder is an attractive method for cutting cast iron pipe since many homeowners have easy access to this tool. To cut cast iron with an angle grinder, you will need to do the following:

- Mark the cut line on the cast iron pipe using chalk or crayon. When using an angle grinder, it is highly recommended that you mark the full circumference of the pipe.

- Use a diamond cutting wheel/blade to cut through the cast iron with an angle grinder.

- Run the angle grinder along your cut line by applying even pressure all the way around the pipe.

- Safely remove the pipe from the plumbing segment after you have completely cut through the pipe.

Cutting Cast Iron using a Snap Cutter

Although a snap cutter is typically the fastest and most effective way to cut cast iron pipe, it requires a snap cutting tool – which many homeowner’s don’t typically have on hand. Therefore, this method is typically more common for licensed plumbers.

To cut cast iron pipe using a snap cutter, you will need to perform the following steps:

- Mark the cut line on the cast iron pipe using chalk or crayon.

- Wrap the chain cutter around the pipe and evenly and tighten it around the pipe on the marked line.

- Apply pressure on the snap cutter handles so that the cutting wheel penetrate into the pipe – snapping it along the line.

Cutting Cast Iron with a Hack Saw (Difficult – not recommended)

Although you can cut cast iron with a hacksaw, it is not easily accomplished. If you choose to try cut cast cast iron with a hacksaw, follow the same steps as cutting cast iron with a reciprocating saw. That is:

- Mark the cut line on the cast iron pipe using chalk.

- Apply even pressure and cut through the pipe using the hacksaw.

- This will likely take 10-15 minutes, depending on the condition of your pipe and blade.

Cutting cast iron with a hacksaw is not easy and will require considerable “elbow grease” to accomplish. As a result, using a hacksaw to cut cast iron is not recommended.

Step 4: Remove the cast iron pipe and replace it with PVC pipe

Once you have cut both ends of the cast iron pipe segment, remove the pipe from the existing plumbing header.

Next, clean the remaining segments of cast iron pipe to ensure that there are no contaminants or sharp edges left on the pipe segments that you cut.

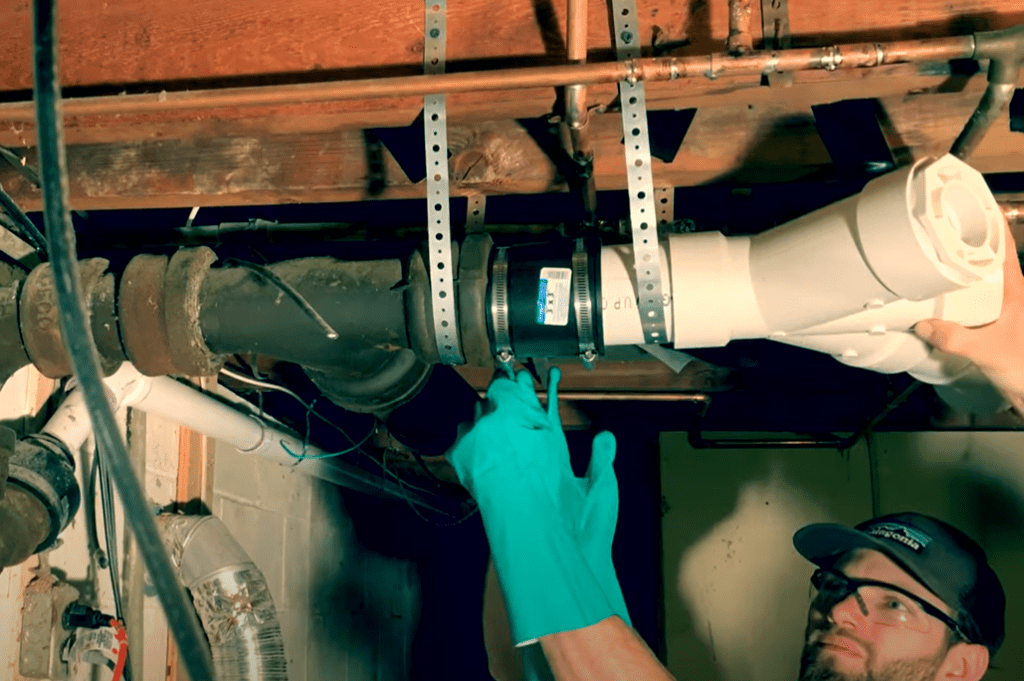

In order to to connect PVC pipe to existing cast iron sewer pipe, you will need to utilize a flexible “Fernco” coupling as shown below:

The size and type of “Fernco” flexible coupling you will need to use will depend on your application. Consult with your local box store or plumbing shop if you need guidance on selecting the correct coupling.

Once you have purchased your “Fernco” flexible coupling, slip one end of the coupling over the existing cast iron segment and slip the other end over the new PVC segment. Next, tighten the ratchet straps to compress the gasket and ensure that you have no leaks.

After replacing a segment of cast iron pipe with PVC pipe, visually inspect the connections to ensure that there are no leaks. If any leaks or dripping is observed at the “Fernco” flexible coupling, continue to tighten the straps until the leak stops.

At this point, you have successfully cut cast iron pipe and replaced it with PVC pipe.

Thanks so much for checking out ATImprovements! If you learned something from this project, you might also like these other DIY Projects:

How to Build a Fire Pit: How to Build a DIY Fire Pit Table (And save hundreds of dollars in the process!) – (atimprovements.com)

How to Install a DIY wire / Cable Railing: DIY Cable Railing – How to Install Cable Railing Step-by-Step – (atimprovements.com)

How to Build Hexagon Shelves: DIY Hexagon Shelves (Honeycomb Shelves) – (atimprovements.com)

How to Patch a Hole in Concrete Foundation: How to Patch a Hole in Concrete Foundation – (atimprovements.com)

Thanks!

DISCLAIMER: This is a reference guide only. Links included in this article might be affiliate links. If you purchase a product or service with the links that I provide I may receive a small commission. There is no additional charge to you! Thank you for supporting ATimprovements so I can continue to provide you with free content each week!